RETAINERS AND COLLARS

Retainers and Collars

The seals are used to create tightness in rotary axes, usually applied in the manufacturing machinery, components and automotive industries.

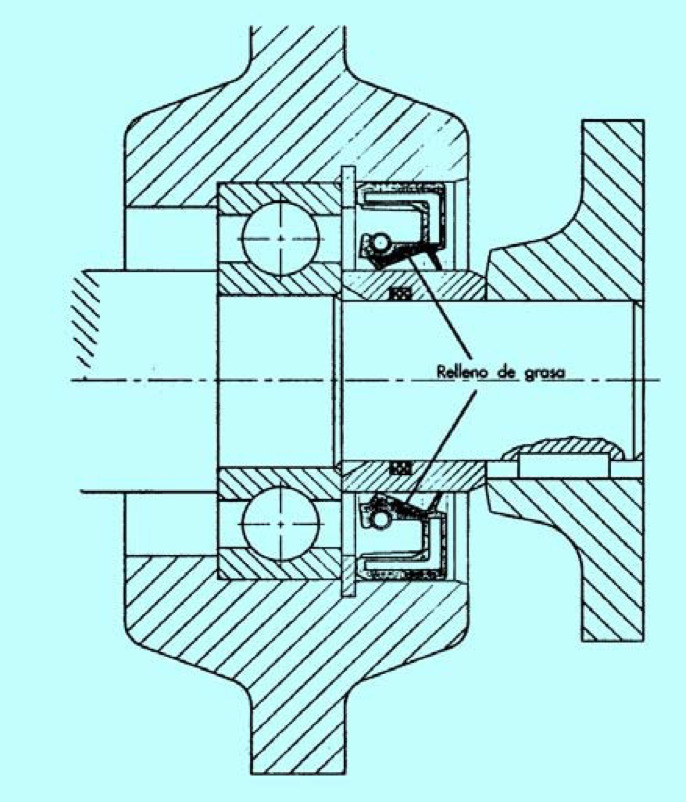

They are intended to guarantee a tightness in viscous, liquid or gaseous fluids and as usual in greases, oils and lubricants.

Main features:

- Metal outer ring coated or uncoated elastomer.

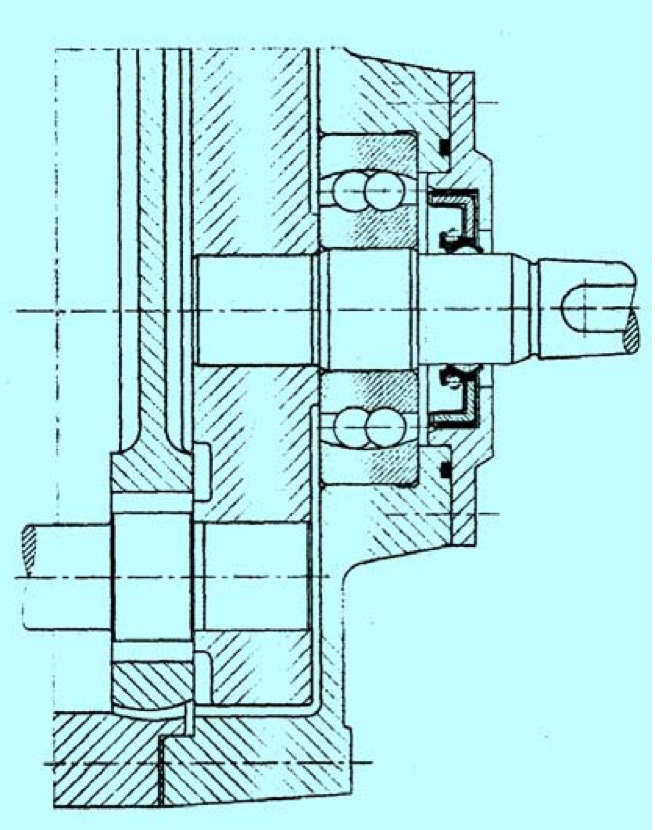

- Sealing lip equipped with a tension spring. Its function is to guarantee the dynamic and static sealing of the axis, that is, both the axis when rotating and at rest.

- Additional lip for applications where greater security against dust and/or dirt from the outside is required.

- Manufacture according to DIN 3760, other models to be consulted.

Related documents

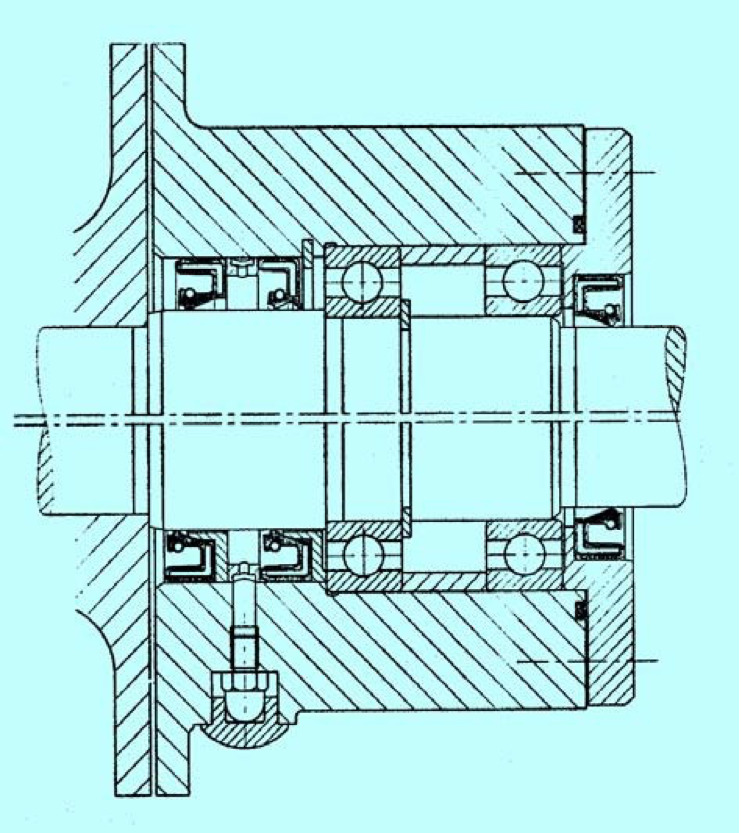

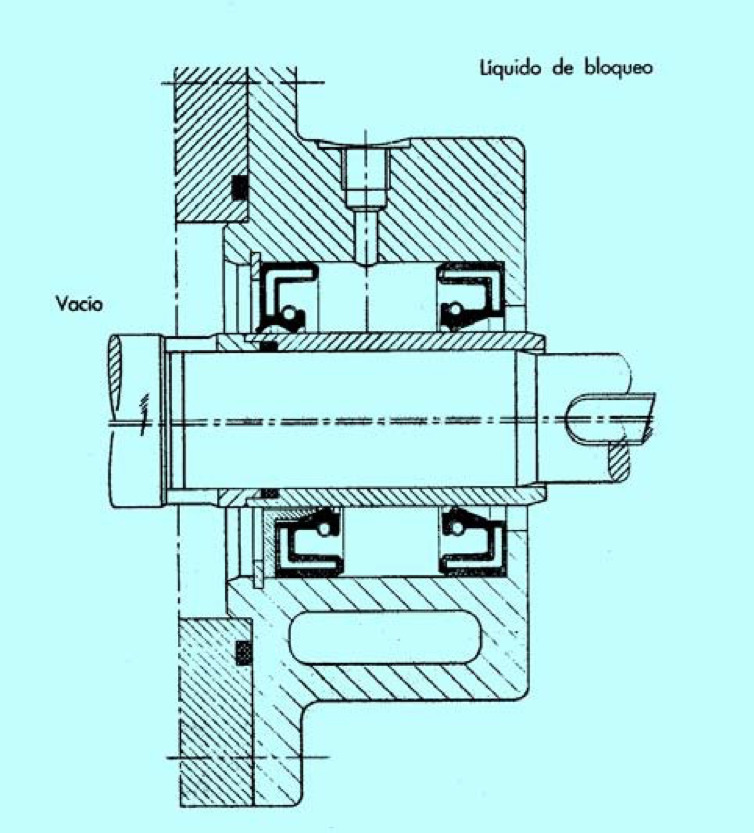

Assembly of radial seals

The allowances indicated by the manufacturer must be strictly observed:

- Material qualities and the axis' machining with Rmax = 6.3 μ.

- Tolerances of h11 for the axis and H8 for the housing.

- Shaft hardness from 45 to 60 HRc.

- Concentricity of the axis from 0.3 to 0.1 mm, according to the rotation speed.

- Dynamic eccentricity between 0.4 and 0.1 mm, according to the speed.

- Rmax housing roughness = 10-25 μ depending on the type of seal.

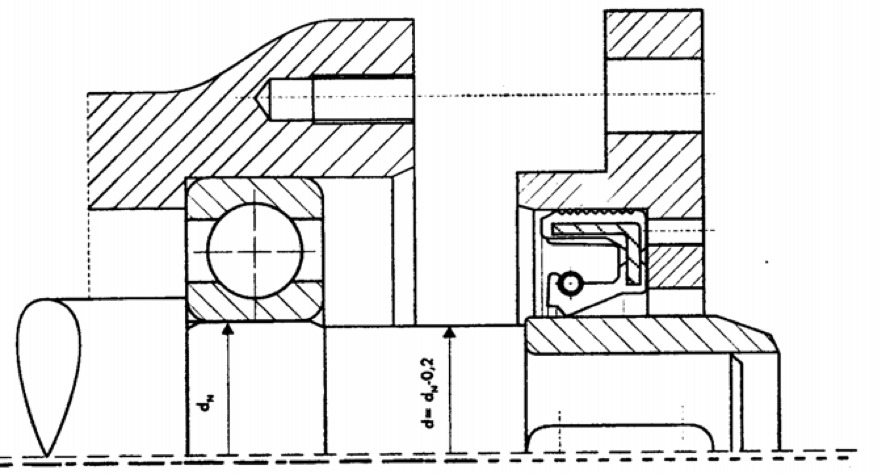

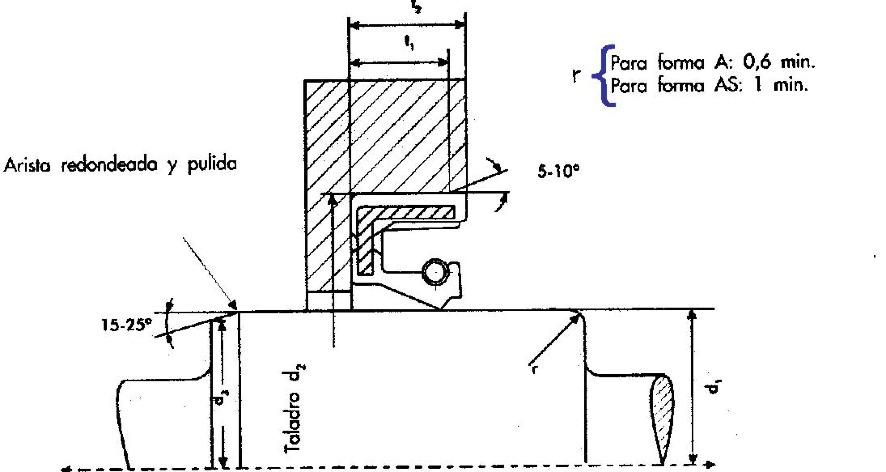

- The use of mounting caps may be required to avoid damaging the retainer:

- It is necessary to use chamfers or rounding radii for the assembly according to the assembly's direction.

- The diameter of the chamfer (d3) is 80% to 95% of the shaft's diameter, and according to its value (between 6 and 500mm)