Sobre NosotrosFijación, Cierre y Estanqueidad

Desde 1970 en el mercado de los materiales y las juntas. Desde 1998 proveedores al por mayor de productos que aseguren la Fijación, el Cierre y la Estanqueidad en todas las áreas de la industria.

Romero Dyscar es una firma interviniente en los procesos productivos, fabricante, importadora y exportadora. Ofrecer unos tiempos de entrega reducidos es esencial para mantener el grado de satisfacción de nuestros clientes. El desarrollo de nuestras actividades, centradas bajo la especialización en fijación, cierre y estanqueidad, nos ha posibilitado adentrarnos cada vez más en el mundo de los proyectos industriales.

DIVISIONES

Productos especializados en adhesivos, selladores, aerosoles y soluciones químicas técnicas adaptadas a distintos procesos industriales

Amplia gama de juntas y elementos para asegurar una hermeticidad perfecta en diversas aplicaciones industriales. Cobre, Aluminio, Caucho sintético, Fibras Sintéticas, Composites, Inox, Caucho-Metal, Acero Zincado.

Soluciones específicas en cauchos y elastómeros técnicos que cumplen con exigentes requisitos de resistencia, durabilidad y adaptabilidad. Cauchos Sintéticos, Moldeado, Extrusión, Mecanizado.

Sistemas completos y componentes de calidad que garantizan uniones seguras y fiables en todo tipo de ensamblajes industriales. Acero al Carbono, Inox, Standards, Aeronáutica.

Desarrollo integral de soluciones técnicas a medida, adaptadas específicamente a proyectos industriales complejos. Proyectos, Válvulas, Tubería, Barra Mecánica, Bridas, Material a Medida.

Productos y componentes esenciales para sistemas de climatización, refrigeración industrial y gestión térmica. Soluciones para fugas y mantenimiento, R-410, R-744, R-134a, 1234yf…

CalidadCertificaciones

Adecuación al clienteMATERIAL A MEDIDA

Desde un principio tuvimos claro que debíamos ofertar productos para las pequeñas y las grandes series. Eso nos ha permitido dotarnos de una gran capacidad de maniobra y poder servir desde cantidades enormes a pequeñas y desde piezas sencillas y normalizadas a las más complicadas y fuera de medida.

Marca Privada

Calidad – Precio – Servicio

La importancia de formar una identidad comercial con productos de calidad es la receta del éxito. Un precio competitivo y un servicio ejemplar marcan la diferencia.

Los famosos son nuestros clientes, nosotros permanecemos en otro plano.

Fijación, Cierre, Estanqueidad

Arandelas, Juntas Y Sellantes

1998

Hole-Lock® AlbaTem®

2003

Made In Germany

2004

Refrigeración Soluciones para Fugas

2007

Nuestras Marcas

AlbaTem, ofrece soluciones químicas avanzadas selladores, adhesivos y aerosoles técnicos de alto nivel que optimizan procesos y mejoran la fiabilidad de cualquier aplicación industrial.

Hole-Lock, nuestra marca de juntas de alto rendimiento, garantía de estanqueidad, resistencia y durabilidad, incluso en las condiciones más exigentes.

DISTRIBUIDORES

I + D

Dyscar impulsa la investigación y el desarrollo de prototipos con un enfoque innovador y tecnológico. Nuestro equipo de I+D colabora estrechamente con empresas e ingenierías para diseñar soluciones a medida.

Aportamos conocimiento y experiencia que permiten optimizar procesos y mejorar la eficiencia de los productos.

Industrias Atendidas

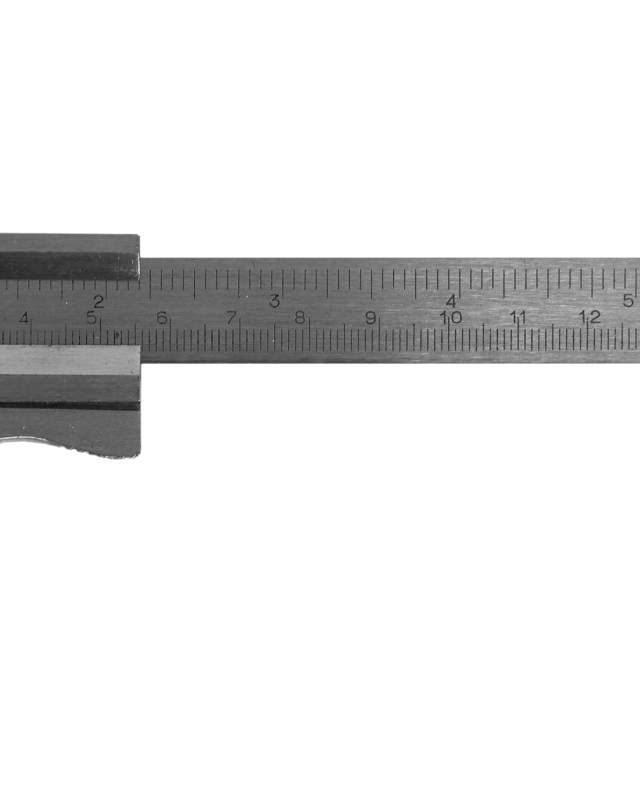

Control de calidad, tolerancia dimensional y geométrica

Tapón de Carter de plástico. Tapón de Carter

Juntas y arandelas para aeronáutica

ContactoCONTACT US

Dirección

Calle Sierra de Guadarrama 22, San Fernando de Henares, Madrid, 28830