Anaerobic

Anaerobic adhesives and sealants are mono-component substances that only react or polymerize with air's absence and with the presence of metal ions, forming an inert plastic polymer that fills the surfaces’ voids; unifying the union. They fill 100% of the free space, they move into the ridges and join the two pieces forming a unique body that absorbs vibrations and shocks, preventing loosening and wear. They are also effective sealants and avoid the surfaces’ oxidation. Excess exposed to air does not cure, does not contaminate, does not cover filters, does not lock valves and can be easily cleaned. These adhesives, with different values of shear strength, temperature, pressure, among other factors, allow for the covering of all the mechanical parts’ fixing and sealing needs.

In certain circumstances anaerobic adhesives require an activator on passive or non-metallic substrates.

The fixers fill these spaces making it so that the elements are held tight; avoiding the loosening even under severe conditions of vibration and impact; the assembly’s efforts are distributed evenly through the useful length of the threads, eliminating the use of mechanical devices such as flat washers, pressure washers, securing nuts, pins, etc. Since there are different types of assemblies, different materials of nuts and screws of various calibers, there are also fasteners of different strengths, different viscosities and different curing times. Depending on your needs, we offer low, medium and high-strength threadlockers.

Traditional cylindrical assemblies require adjustments or interventions, which in the end only means that one of the bodies has a larger diameter than the one that will be contained within it. No matter how fine the machining is to provide the adjustments, there will always be surface irregularities that prevent the total contact between the pieces and generate relative movement between them, producing wear and loss of the adjustment.

The retainer products act by filling the spaces between the pieces, forming resistant, durable and precise assemblies; eliminating wear and tear and maintaining the equipment’s original dimensions. They are formulated in different viscosity ranges, ability to seal quickly and without problems with pipe joints, plugs and high-pressure fluid power systems (Hydraulic/Pneumatic).

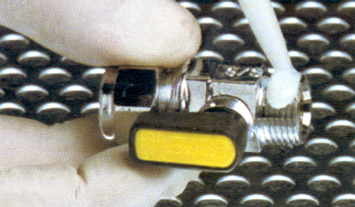

Anaerobic sealants are used to quickly and seamlessly seal the plumbing joints, plugs and high-pressure fluid power systems (Hydraulic/Pneumatic).

Easily applicable and reliable, with or without loads, with the use of hand tools provide an immediate seal which is resistant up to 1,000 psi. They do not pollute, shrink or break in the most adverse conditions.

Pressure is a fundamental factor in flanged systems for the selection of the joint’s material, since it has less thickness when put under higher pressure; the anaerobic sealants or substitutes for joints are applied as a gel on the seal’s surface and when joining the pieces it is spread in the sealing width allowing for metal-metal contact and entering the surface irregularities and forming a plastic joint which is very resistant to high pressures and chemicals.

Reviews

There are no reviews yet.